How a Membrane Switch Boosts Individual Experience and Tool Effectiveness

Just How Membrane Layer Changes Add To the Sturdiness of Electronic Control Panels

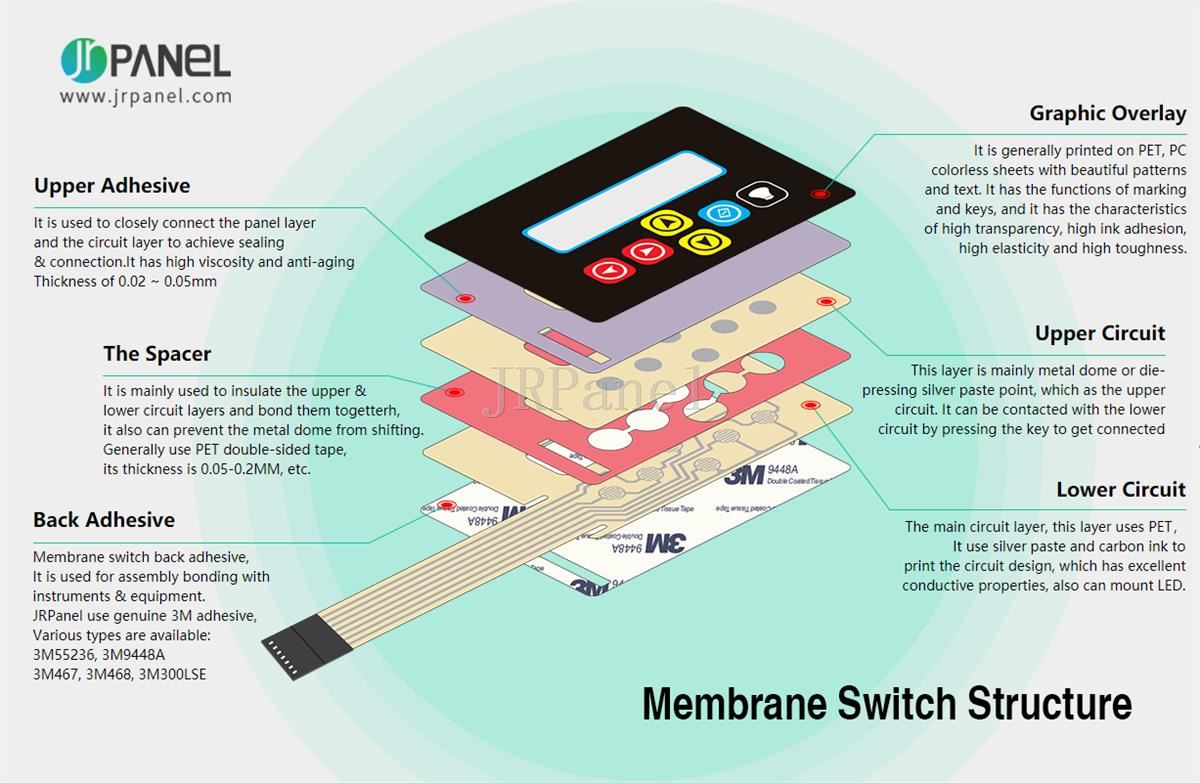

Membrane layer switches play an essential function in enhancing the sturdiness of digital control panels, primarily through their multi-layered construction which supplies efficient security against ecological variables such as wetness and dirt. The absence of moving components dramatically lowers the possibility of mechanical failures, making membrane layer switches over ideal for demanding applications.

Interpretation of Membrane Buttons

Membrane buttons are made to be thin and light-weight, making them ideal for applications where space is limited. They can be made in numerous shapes, dimensions, and colors, supplying flexibility in layout that meets visual and useful requirements. In addition, membrane layer switches can include various modern technologies, such as tactile feedback and LED signs, improving user experience.

Because of their construction, membrane layer buttons are commonly resistant to dust, moisture, and general wear, adding to their resilience popular environments. Their seamless design not just facilitates very easy cleaning yet likewise decreases the danger of mechanical failure, making them a preferred selection for suppliers looking for dependable individual interfaces in their electronic control panels.

Defense Versus Ecological Variables

The design of membrane layer changes naturally supplies a level of defense against numerous environmental variables, which is vital for keeping functionality in tough problems - Membrane Switch. These buttons are generally constructed with layers of flexible materials that shield internal parts from moisture, dust, and impurities. By encapsulating the wiring, membrane layer switches minimize the risk of short circuits and corrosion, which can substantially impair efficiency

Furthermore, the use of robust adhesives and sealers during production boosts their resistance to ecological difficulties. Membrane buttons can withstand direct exposure to chemicals and solvents, making them ideal for industries such as food processing and medical care, where hygiene and sanitation are critical. Their smooth surface layout additionally protects against the build-up of dust and germs, promoting easier cleansing and upkeep.

Temperature variations are one more ecological concern, and membrane buttons are crafted to operate successfully across a wide variety of temperature levels (Membrane Switch). This adaptability makes certain that control panels continue to be operational in numerous settings, from commercial atmospheres to customer electronics

Effect on User Communication

User communication with electronic control board is substantially influenced by the design and performance of membrane buttons. These buttons supply a responsive interface that enhances the overall individual experience, enabling for user-friendly navigation and control. Their receptive nature ensures that individuals obtain prompt comments upon activation, which is critical for jobs needing accuracy and effectiveness.

Additionally, the smooth surface of membrane layer changes promotes simple cleansing and upkeep, promoting customer confidence in the integrity of the user interface. This cleanliness is specifically crucial check my reference in settings where health is paramount, such as medical or food processing setups. In addition, the compact and light-weight layout of membrane changes adds to the aesthetic appeal of control panels, urging user involvement via a modern-day and streamlined look.

Furthermore, the integration of visual elements, such as published icons and backlighting, helps individuals rapidly determine features, reducing the finding out contour associated with new devices. Because of this, users can operate tools better, leading to enhanced productivity and complete satisfaction. In recap, membrane layer switches play a crucial function in enhancing customer communication by integrating capability, looks, and simplicity of use, ultimately leading to enhanced functional efficiency.

Design Versatility and Customization

Layout flexibility and modification are vital facets of membrane buttons, allowing manufacturers to tailor electronic control board to details applications and user needs. This adaptability permits the assimilation of different layout aspects, such as colors, graphics, and textures, which can enhance the visual allure and customer engagement of the control board.

Membrane switches can be customized in dimension and shape, check this site out suiting a wide variety of gadgets and applications, from commercial equipment to consumer electronic devices. This adaptability makes sure that makers can produce user-friendly interfaces that align with customer assumptions and functional demands. Furthermore, the capability to include one-of-a-kind attributes such as backlighting or responsive feedback even more improves usability, enabling a more interactive experience.

In addition, the production procedure for membrane layer changes supports the quick prototyping of styles, making it possible for suppliers to repeat and improve their principles swiftly. This ability not only speeds up the growth timeline yet additionally makes sure that the last product meets certain useful and aesthetic criteria.

Cost-Effectiveness and Longevity

Cost-effectiveness and durability are significant benefits of membrane layer buttons, making them an eye-catching alternative for makers and end-users alike. These switches are generally more economical to produce than conventional mechanical switches, largely due to their simplified production processes and the decreased variety of elements required. This expense advantage extends not only to first manufacturing but likewise to long-lasting operational expenses, as membrane switches frequently need much less upkeep and have a reduced failing rate.

Furthermore, the long life of membrane layer switches contributes to their total worth. Created from sturdy materials, they are immune to ecological variables such as moisture, dust, and chemicals, which can cause premature wear in other switch kinds. The lack of relocating company website components decreases mechanical failing, allowing membrane layer changes to preserve functionality over expanded durations.

This toughness is especially advantageous in applications needing consistent efficiency under requiring problems, such as medical tools and industrial tools. Eventually, the combination of cost-effectiveness and longevity makes membrane layer changes a financially practical selection for makers, giving trusted services that endure the test of time while enhancing monetary considerations.

Verdict

In conclusion, membrane switches significantly boost the sturdiness of electronic control panels through their durable building and safety attributes - Membrane Switch. On the whole, membrane layer switches over stand for a trustworthy and cost-effective selection for boosting the longevity and functionality of electronic control systems.